QUALITY

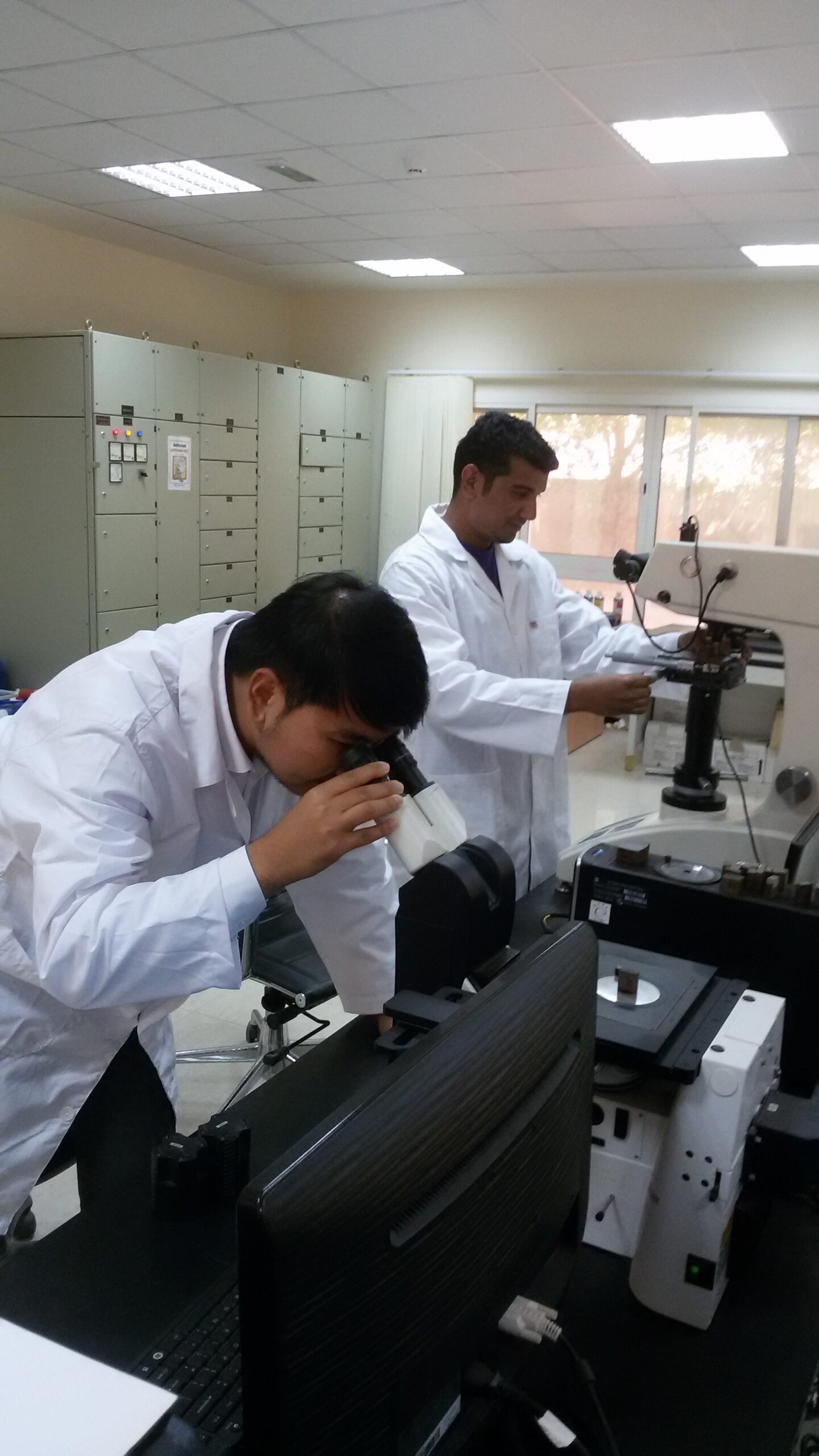

SeAH Steel UAE is highly experienced in dealing with customer requirements and specifications. Its quality assurance system is certified according to ISO 9001:2015 standards. The project-oriented organization allows dealing with main international standards ASTM, ASME, API, EN, DNVGL, customer requirements and any project specifications. The mill is equipped with an in-house accredited laboratory that allows verifying material features, determining chemical and mechanical properties, controlling the quality of welds, ensuring compliance with regulations and above all guaranteeing the highest quality of the products.

DESTRUCTIVE TESTING

- Product Analysis/Chemical Analysis – Chemical Analysis (Optical Emission Spectrometer)

- Tensile Test at room temperature and hot tensile test – Tensile Test at Room Temperature

- Bend Test – Guided Bend Test

- Impact Test up to -196°C – CVN Test up to -50°C

- Micrographic Examination up to 500X – up to 100X

- Macrographic Examination – Olympus (Up to 4.5X)

- Hardness Test (also NACE MR 01-75) – Vickers’s Micro Hardness test as per ASTM E92

- Drop weight tear test (DWTT), Hydrogen-Induced Cracking (HIC) – DWTT as per API RP 5L3 and HIC as per NACE TM 0284

- Sulphide Stress Corrosion Cracking (SSCC) – Alternate to this test is the Four Point Bend Test as per ASTM G39

NON DESTRUCTIVE TESTING

- X-Ray Testing (Radiographic & Radioscopic examination & Digital) – Real-Time X-Ray & Digital X-Ray (TV Screen type)

- Ultrasonic Examination (and PAUT) – Outsource Activity

- Magnetic Particle Examination – Outsource Activity

- Hydrostatic Test – In-house test (Capacity up to 59 MPa)

Main Approvals

| API Q1 | 2011 MAY |

| API 5L | 2011 MAY |

| ISO 9001 | 2011 MAY |

| API 2B | 2012 MAY |

| TAKREER | 2012 JUL |

| FERTIIZER | 2013 MAR |

| API J/H | 2013 MAY |

| ADCO | 2013 DEC |

| ADGAS | 2014 JAN |

| ADMA-OPCO | 2014 APR |

| ADWEA | 2014 JUL |

| ISO 14001 | 2014 NOV |

| ISO 18001 | 2014 NOV |

| CE | 2015 APR |

| NIGC | 2015 AUG |

| KALA NAFT | 2015 AUG |

| ZADCO | 2016 JUN |

| GASCO | 2016 JUN |

| RAS GAS | 2016 DEC |

| ISO 3834 | 2021 NOV |

| DNVGL | 2021 DEC |

ADVANCED EQUIPMENTS

- Sour Serviced Lab. (HIC/SSCC)

- Automatic Ultra-sonic Tester

- DWTT Room

- Cold-Expander

- Two(2) Heat-treatment Furnances (Max. temperature at 960oc)

- Hydrostatics (Max. 600kgf/cm2 up to 120″)